TV panel technology

New technologies for plasma and LCD displays are only months away – just as they have been for several years. But the whole issue of the quality of TV panel technology remains as contemporary as ever.

There is a lot of blather about new TV panel technologies. In truth, some of them sound pretty exciting, and two have actually been introduced in some form.

However, they are not likely to displace LCD or plasma any time soon.

ADVERTISEMENT

Before examining these new technologies, let us remind ourselves how the two current systems work.

The simplest is the LCD display. One of the distinguishing characteristics of liquid crystals is that their optical properties change in the presence of an electric field.

In that way, a very small amount of power can be used to switch liquid crystal pixels between transparent and nearly opaque, and anywhere in between (at least when compressed between polarised glass plates). This controls the emission of light from a backlight.

The main disadvantage of LCD displays is that the liquid crystals will not go completely opaque, so they tend to glow a little in low-light situations, even if the image they are displaying is supposed to be completely black.

Plasma TVs work very differently. Each dot consists of a small glass ‘cell’ containing a gas.

When an electric field is applied, the gas ionises (splits into positively and negatively charged particles) and the ions race towards the electrodes. They clash there, causing ultra-violet light to be generated. This strikes a coloured phosphor on the cell and causes it to glow.

The main disadvantage of plasma is ‘burn- in’. Phosphors tend to wear out – more rapidly with longer exposure. Modern designs are fairly resistant to this, but static menu displays should not be permitted over long periods. In addition, they tend to have difficulty with deep blacks.

The ionisation process needs a bit of a kick along to get started (this is called ‘pre-charge’), so they won’t ramp smoothly all the way up from black. Instead, they have to be kept glowing a little. Pioneer’s next-generation of displays are expected to overcome this, allowing pure black display.

A new display technology that has been talked about for a very long time is surface-conduction electron-emission display or, more commonly, surface emission display (SED). In some ways, this is a return to good old-fashioned CRT technology.

Remember how CRTs work? At one end of a tube you have a cathode that throws electrons out. These are guided by magnetic fields, filtered by shadow masks, and eventually make their way to the other end of the ‘almost vacuum’ in the glass tube. There they strike phosphors, generating an image.

With SED, each third of a pixel has its own glass tube (there are three per pixel in order to produce red, green and blue colours). Instead of tens of centimetres, each tube is extremely short, and the throw distance of the electrons is accordingly short.

There is no need for a magnetic field to guide the electrons or for a shadow mask. The grid of picture elements is preformed by the location of these cells.

SED panels should allow CRT levels of black (the first products promise contrast ratios of 50,000 or 100,000:1) because they don’t require the plasma kick-start.

They ramp up smoothly from black. However, they are likely to be subject to similar levels of ‘burn-in’ as plasma, because that is a phenomenon of phosphor-based displays.

The real problem is that products have been promised within the year for the past several years. It turns out that legal problems were holding up its release.

Now the technology is being developed exclusively by Canon (Toshiba had to withdraw under a settlement with Applied Nanotech, which has control over certain components of the technology).

With all this fiddling around, it’s likely that by the time SED is released it will yield little advantage over next-generation plasma TVs. Industry noises suggest that SED will be released, at least initially, only for professional applications because it is likely to be very expensive.

OLED stands for organic light-emitting diode. We are talking about a solid-state diode made from carbon and hydrogen-based chemicals, rather than silicon-based materials (organic chemistry is basically the chemistry of carbon and hydrogen compounds).

Unlike SED, OLED is actually here. You can walk into a shop somewhere and purchase an OLED display. OK, the shop is in Japan or North America, and a 28cm TV will cost you $US2,500. Nonetheless, you have to start somewhere (the first 42-inch SD widescreen consumer plasma set that I saw cost $30,000).

OLED displays produce the light themselves and do not require the structural support and rigidity of LCD and plasma displays. Consequently they are very thin and relatively flexible.

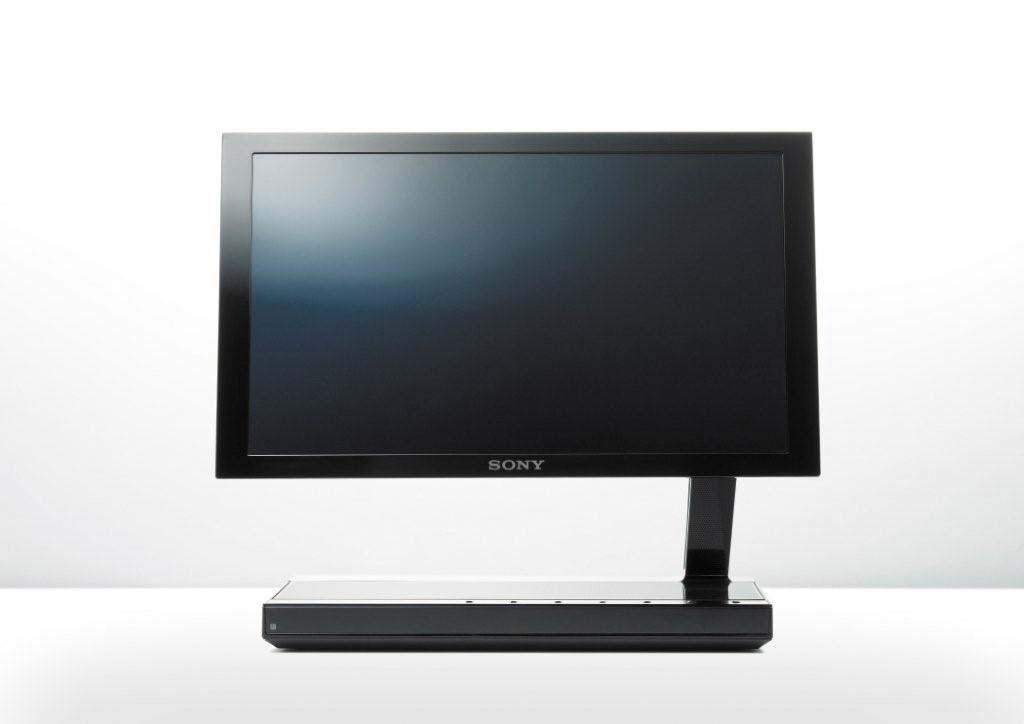

For example, the aforementioned 28cm TV is the Sony XEL-1. Its display panel (offering 960 by 540 pixels in a widescreen aspect ratio) is apparently just 3mm thick. Last year Sony demonstrated another panel, the same size, that was only 0.3mm thick.

Sony says the XEL-1 has a contrast ratio of an extraordinary one million to one. It means that if you put the TV in a completely dark room, switch it on and display a purely black image, you will not be able to see it at all.

Now all we have to do is wait for the size to increase and the price to fall – if the device can get enough of a foothold in a market already dominated by plasma and, especially, LCD.

Another product that was promised within months a couple of years ago is the laser TV. Strictly speaking, this isn’t a panel TV at all but a DLP rear-projection TV. It’s claimed that this will be a relatively shallow DLP, but it will still be somewhat thicker than regular panels.

The difference with a laser TV is that instead of using a lamp producing white light, three laser devices are employed.

In fact, neither blue nor green lasers suitable to the purpose have been developed. However, the developers of laser TV have managed to work around this by having tuned, infra-red lasers then doubling their frequencies externally to deliver the correct green and blue colours.

Why bother? After all, single-chip DLPs achieve this just by spinning a colour wheel in front of a white lamp. There are three specific advantages to using lasers.

First, the technique is highly efficient. With a regular DLP, the bulk of the energy produced by the lamp is discarded, and only relatively narrow portions of it – in the red, green and blue wavelengths – are permitted to contribute to the picture. With lasers driving the show, only those wavelengths are generated in the first place.

Laser TV proponents say a laser TV would use just one-quarter of the power of a plasma or LCD.

Second, with only very precisely defined wavelengths being produced for each of the three colours, greater control can be exercised in mixing the colours to allow a broader range of colours – or so it is said.

Third, due to the known wavelengths of the light involved, the digital micro-mirror device that controls the progress of the light to the screen can be optimised.

However, there is some talk about the phenomenon of ‘speckle’, in which a lot of light in a narrow waveband can produce random fluctuations, producing a somewhat ‘dotty’ result. Demonstrations so far don’t seem to have resulted in speckle.

Early this year Mitsubishi demonstrated a 165cm 1080p model at CES in Las Vegas. You can’t buy one just yet, but there is a fair chance they will be out within a year.

Naturally, if I can get my hands on an SED, OLED or Laser TV, you will hear all about it in this publication as we assess the promises against the reality.

-

ADVERTISEMENT

-

ADVERTISEMENT

-

ADVERTISEMENT

-

ADVERTISEMENT